802 Commonwealth Avenue, Boston, MA

[CHRISTINA] LU JIN

Lighting | Electrical Option

BUILDING STATISTIC

Building Name

Location and Site

Building Occupant Name

Occupancy or Function Types

Size (total square feet)

Number of Stories

Primary Project Team

Dates of Construction

Project Delivery Method

Boston University School of Theater

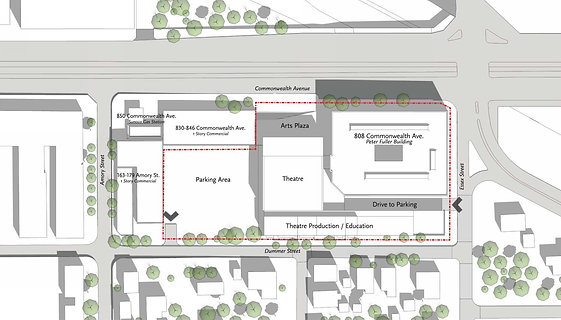

820 Commonwealth Ave., Boston, MA

Boston University (students, faculties and guests)

Performing Arts / Education

80,000 SF

4 stories above grade; 6 total levels

Owner | Boston University

Project Manager | Stantec

Construction Manager | BOND Brothers

Building Architects | Elkus Manfredi Architects

Lighting Consultants | Auerbach Glasow French

Theatre Design | Auerbach Pollock Friedlander

MEPF Engineer | Vanderweil Engineers, LLP

Structural Engineer | Amman & Whitney

Landscape Architect | Mikyoung Kim Design

June 2016 – August 2017

Design – Bid – Build

BUILDING OVERVIEW

Boston University Theatre Center (BUTC) is a steel-beamed, glass-filled vibrant modern performance complex, located in the middle of BU’s Charles River Campus, the contrast of BUTC with its surroundings will change the dynamic tremendously and promote a more creative community.

This state-of-the-art performance complex has couple of highlighted spaces, including a featured high-bay lobby area, a large-scale multi-functional theatre space (aka. “Black Box”) with a seating capacity of up to 250 depending on the configuration of the stage, and also an exterior landscaped plaza fronting the Commonwealth Avenue.

Other than the featured spaces, BUTC also has a full complement of backstage performance/ technical support (storage, dressing rooms, production offices, kitchenette); shop spaces (scene shops, tool areas with dust collection and paint application, costume creation and storage); design and technical faculty offices; teaching spaces (classrooms, conference rooms, lighting/ audio labs); and support spaces such as restrooms, circulation and back of house areas.

Underneath the 4-story theatre center is a two-level subsurface parking garage (containing 182 parking spaces) in addition to the reconfigured landscaped surface parking lot (containing 104 spaces) makes up a total of 286 parking spaces.

HISTORICAL ELEMENTS

After a history of 33-year residence on the other side of the campus at the old Boston University Theater. This new modern performance complex – BUTC is now located in the middle of the BU’s Charles River Campus, to bring the performing art programs back close to BU College of Fine Arts (CFA). Which has allowed School of Theatre to end its long-standing tradition of cross-disciplinary collaboration through its academic outreach.

BUTC not only made it possible for the School of Theatre to be no longer split in two separate locations, but provides more opportunities for BU students, faculty, and staff to attend productions. In addition, this vibrant community could also promote a more creative environment, promise strengthened professional education, and increase the connectivity among collaborative artists at the same time. Most importantly the contrast of BUTC with its surroundings will change the dynamic tremendously and will be attractive to the student body and the general public.

SUSTAINABILITY FEATURES

The building is being designed to achieve Gold-level certification under USGBC LEED V3 2009, BUTC’s design team approaches the sustainable intent from couple of different aspects. Firstly, high performance wall material and roof constructions are used to avoid thermal bridging, also the combination of the high-performance glazing plus the daylight sensor made it possible to utilize the solar energy to the building’s advantage, and decrease its dependence on artificial light at the same time. Secondly, the use of natural ventilations could effectively bring down the air-conditioning load during favorable outdoor conditions. Thirdly, due to the diverse thermal design parameters of different types of spaces, sensitive location and definition of borders between zones are treated differently (like air curtain, etc.) to reduce thermal losses. Openings or fans for deliberate, controlled airflow are also designed between zones. In addition to the above, high efficiency HVAC systems like Demand-Controlled Ventilation, Exhaust Air Heat Recovery, Building Automation System, and Water-Side Economizers are also being considered and utilized as a contribution towards the sustainability strategies.

OVERVIEW

High-performance glazing

High-performance wall and roof constructions which avoid thermal bridging

Use of natural ventilation during favorable outdoor conditions

High-efficiency lighting design, including extensive use of LED fixtures

Sensitive location and definition of borders between zones to reduce thermal losses

Design of openings or fans for deliberate, controlled airflow between zones

Appropriate selection and evaluation of sound-absorbing materials

ENERGY EFFICIENT STRATEGIES

Demand-Controlled Ventilation

Demand controls enable the building to set back operations when a particular space is not in active use. The monitoring is connected through a CO2 sensor that indicates when occupants are present and require ventilation.

At less than full building occupancy, the DCV system can reduce ventilation air volume, thus reducing the energy required to heat or cool and dehumidify the ventilation air.

Exhaust Air Heat Recovery

With this system, heat is exchanged between the outgoing exhaust air and the incoming ventilation air. During the heating season, warm exhaust air helps to pre-heat the incoming outdoor air; during the cooling season, relatively cool exhaust air helps to pre-cool the incoming outdoor air. The heat recovery device will be between 50 percent and 75 percent efficient in capturing heat (or “coolth”) that would have otherwise been exhausted.

Building Automation System (BAS)

The design incorporates a Building Management System that can aid in the maintenance of the mechanical systems, ensuring safety and maximum energy optimization. When the system experiences an uptick of unusual energy use (as defined by the building staff), the appropriate point person for maintenance will be alerted.

High-Efficiency Chillers

The water-cooled chillers currently included in the design operate significantly more efficiently than comparable air-cooled chillers or packaged rooftop units.

Water-Side Economizer

A plate-and-frame heat exchanger will allow cooling tower condenser water to cool the building during the wintertime, also allowing the chiller plant to remain off.

Condensing Hot Water Boilers

The design includes condensing boilers, which operate at higher efficiency levels than conventional hot water boilers.

High-Efficiency Lighting

LED light fixtures are used throughout the building, saving energy compared to compact fluorescent technology.

Fan Coil Units with EC Fan Motors

Electrically-commutated (EC) fan motors allow the fan coil units (FCUs) to use less fan energy than typical FCUs.

PRIMARY ENGINEERING SYSTEMS DISCRIPTION

ELECTRICAL

CONSTRUCTION

LIGHTING

MECHANICAL

STRUCTURAL

BUILDING MECHANICAL SYSTEM + EQUIMPENTS

The entire building mainly uses VAV. 57 FCUs condition supply air to each space. 10 exhaust surface mounted diffusers and 10 supply air diffusers controlled by volume dampers are used in both underground park spaces. 4 CO and Nitrogen sensors detect waste gas concentration and send to control system to adjust supply and exhaust airflow rates. 2 Rooftop units (RTU 1&2) of total 8,600 and 18,600 cfm airflow rates respectively serve the highlight three-story high Black Box Theatre and Lobby. The surrounding support area is conditioned by a 494 MBH Energy recovery unit along with Fan coil units. A 13,000 cfm Make up air unit (MAU-1) on the roof conditions outside air only and uses plenum to supply OA to paint area. The other 3 MAUs, MAU-2&3 of total 13,880cfm and MAU-4 of 2,800cfm provide fresh air to kitchen area. Also, 4 roof exhaust fans suck out kitchen fume. Two 250 ton cooling towers and a packaged chiller/boiler plant located on the roof provide chilled and hot water to satisfy various building load. The packaged plant includes two chillers of 125 tons which use R-134a refrigerant, and two boilers of 2,000MBH.